1、安装简便,施工高效,可缩短建筑周期——

1. Easy installation, efficient construction, construction period to be shortened——

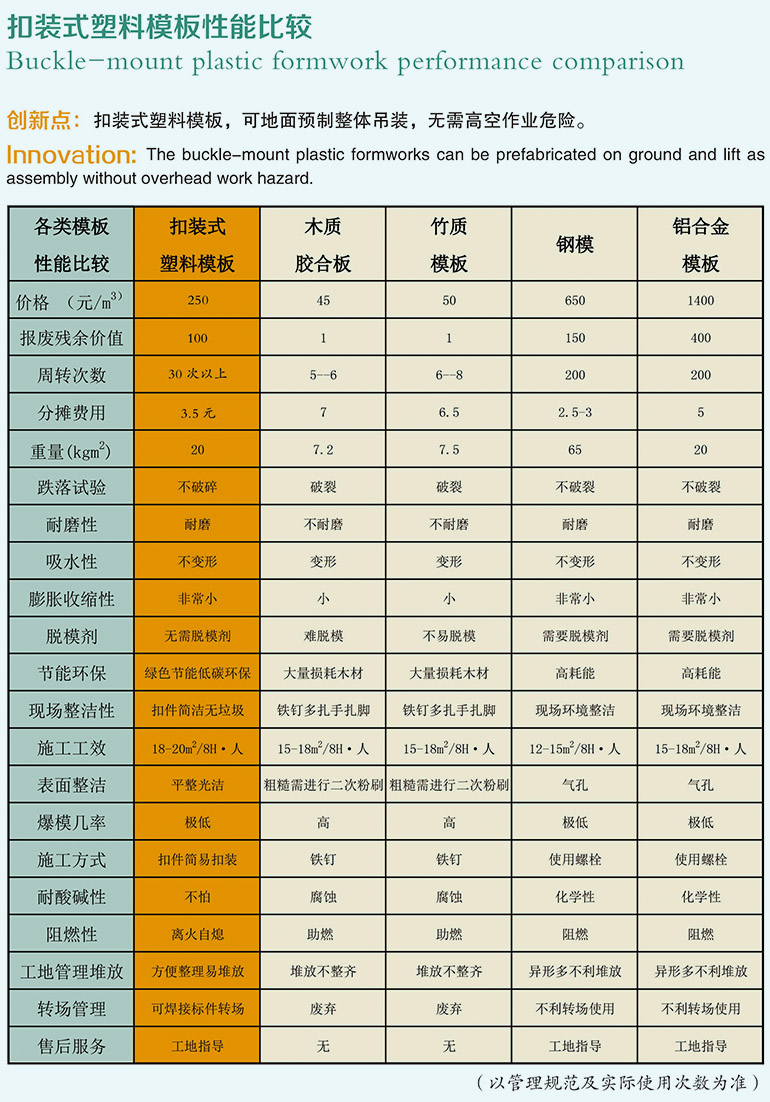

扣装式中空塑料模板--重量轻,平均重量在20kg/m2;扣装简便,工艺简单,完全由人工拼装(亦可在地面预制完成后整体吊装),与木模板相比,局部拼装梁柱可提高工效;不需要技术工人,只需在安装前对施工人员进行简单的培训即可。

Buckle-mounted hollow plastic formwork – light weight, with average weight as 20kg/m2; easy buckle installation, simple technology, complete manual assembly (integral hoisting after completion of prefabrication on ground is also available), local assembly of beam column will improve the work efficiency compared with the timber formwork; technical workers are not required, and only simple training is required for construction personnel before installation.

2、裁接灵活,成本超低,循环使用次数多——

2. Flexible cutting and jointing, ultra low cost, cycle use for multiple times——

扣装式中空塑料模板--标准件可任意裁切,可焊可接可钻,损耗小,可塑性高,管理规范施工,可循环使用次数多;废旧模板可回收再利用,经济价值高,模次分摊成本越低。

Buckle-mounted hollow plastic formwork – the standard component is subject to arbitrary cutting, welding, jointing and drilling, with low loss, high plasticity, management of normalized construction and multiple times of cycle use; the waste formwork can be recycled for reusing. The more economic value is, the less apportioned cost of formwork will be.

3、稳定性好,承载力强,耐寒耐热不变形——

3. Good stability, strong bearing capacity, cold & heat resistant and non-deformable

扣装式中空塑料模板--经专用扣件组装完成后,整体框架稳定性高,单点承载力强,每平方模板可承受2000公斤以上重压;其耐寒、耐热、抗老化、不变形、抗冲击、高效阻燃等特点十分突出,是传统模板无法企及的。

Buckle-mounted hollow plastic formwork – after completion of assembly with special buckles, the stability of overall frame is high, and single-point bearing capacity is strong, with the formwork per square meter bearing the weight of 2000 kg and above; its characteristic such as coal resistance, heat resistance, aging resistance, non-deformation, shock resistance and efficient flame retardance are very dominant, which cannot be excelled by traditional formwork.

4、垂直平整,墙体光洁,可用作清水混凝土面板——

4. Square and flat, smooth and clean wall, can be used as panel of bare concrete——

扣装式中空塑料模板--在浇筑混凝土后,因塑料表面光滑,不易与水泥粘结,垂直度、平整度、观感度良好。拆除模板后的混凝土表面,可达到清水混凝土的要求,无需进行二次粉刷,可节省部分人工粉刷费用。

Buckle-mounted hollow plastic formwork – after placing the concrete, it will not bond with the cement due to the smoothly plastic surface, and the perpendicularity, flatness and aesthetics are good. After removing the formwork, the concrete surface can meet the requirement of bare concrete, and second painting is not required, which will save the painting cost of part workers.

5、应用广泛,拆装灵活,进场转场成本低——

5. Broad application, flexible disassembly/assembly, low cost for arriving and transition——

扣装式中空塑料模板--可塑性高,适用于楼板、墙体、梁柱、楼梯等各种位置使用;全部扣件拼装,拆装十分简便快捷。标件进场、转场速度快。同时,可裁可钻可焊可接的特性,再次使用于新建筑项目时,无需更换订做,有效降低建设成本。

Buckle-mounted hollow plastic formwork – with high plasticity, it is applicable to those positions such as floor slab, wall, beam column and stairs; total buckle assembly makes the disassembly/assembly very simple and rapid. The arriving and transition speed of standard components is fast. Meanwhile, with the characteristic of cutting, drilling and welding availability, the replacement and customization are not required when it is applied in new construction project, which will reduce the construction cost efficiently.

6、整体吊装 安全性高,减少高空作业危险——

6. High safety of integral hoisting, reducing the risk of working high above the ground——

扣装式中空塑料模板--全部采用扣件安装,可按尺寸在工厂或工地拼装作业,以梁底为坐标,整体吊装。从而达到业界提倡的建筑工业化、模块化。大大减少了高空作业人员数量,使得施工安全系数大幅提高。同时,扣件式拼装无需使用铁钉,免除满地铁钉误扎人脚的担忧。

Buckle-mounted hollow plastic formwork – with total installation via buckles, the assembly work can be carried out in the factory or on construction site according to dimension. Integral hoisting is carried out with beam bottom as the coordinate. Therefore, the building industrialization and modularization advocated in this industry can be achieved. The number of personnel for working high above the ground will be decreased dramatically, which will improve the safety factor of construction significantly. Meanwhile, iron nails are not required for buckle-type assembly, which will eliminate the worry about hurting the feet by those nails.

7、重复使用,环保整洁,塑料残余价值高——

7. Reuse, environmental and clean, high residual value of plastic——

扣装式中空塑料模板--均可重复使用,破损模板可由公司回收循环再利用,残余价值高。符合国家提倡的循环经济、绿色环保,低碳的战略方针。组装完成及拆除完成后现场无任何模板垃圾,施工环境安全干净整洁,完全达到文明施工标准。

Buckle-mounted hollow plastic formwork – it can be reusable, and the damaged formwork will be recycled by the company for reusing purpose, which makes high residual value. It conforms to the strategic policy of circular economy, green and environmental protection and low carbon advocated by the country. After completion of assembly or disassembly, no formwork garbage will be left on site, and the construction environment is safe, clean and neat, which meets the civilized construction standard completely.

扣装式中空塑料模板早拆体系

Early removal system of buckle-mounted hollow plastic formwork

|

|

|

|